Services

Menu

Menu

Redefining Excellence

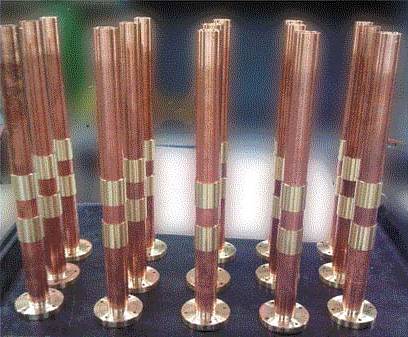

Brazecom Industries offers a wide variety of metal joining technologies and heat-treating processes. From commercial to military applications, we can help you solve your most difficult brazing needs. Specializing in microwave components and assemblies that often require dissimilar metals, we have the expertise and knowledge to deliver you high-quality parts at a competitive cost.

Services include: Brazing and Soldering - filler materials include copper, silver, indium, gold, and nickel.

Vacuum Furnace and Heat Treating

Pressure and Helium Leak Testing - pressures up to 500 psi and vacuum to1.0 x 10-9 cc he/sec

Sandblasting- media include glass, soda and silicon carbide

Brazecom Industries also offers turnkey services. From a "one-off" prototype part to large production runs, we have the ability to accommodate our customers.

Torch & Induction Brazing

Brazecom Industries offers complete R&D and engineering services for your brazing project. We can develop from a single piece to turnkey production runs. We offer Vacuum furnace brazing and torch brazing. Excellent metal joining solution for dissimilar metals.

Materials

Braze Alloys

Vacuum Furnace Brazing

Vacuum furnace brazing is used for various metal joining processes. It takes place in a water-cooled chamber that is evacuated below atmospheric pressure. Assemblies that are processed in a vacuum are bright and shiny clean. The vacuum atmosphere prevents the oxidation of parts. Vacuum brazing is particularly useful where base metals are processed that adversely react with other atmospheres like Nitrogen or Argon.

Vacuum brazing is widely used for brazing base metals of stainless steel, superalloys, and carbon low alloy steels. Vacuum brazing offers a combination of high cleanliness and uniform heating and cooling or rapid cooling. It is ideal for oxidation-sensitive materials such as those used in the aerospace industry.

Brazecom Industries offers the following features and benefits

Heat Treatment

Vacuum furnace heat treating is used to alter the condition or properties in metals or metal alloys. The advantage of heat treatment in a vacuum atmosphere is that it keeps metals pristine clean, and with no surface oxides. Vacuum can virtually eliminate post-heat treat cleaning. The basis for heat-treating can include the following:

Leak Testing

Pressure and Helium Leak Testing

Helium Leak testing is a nondestructive examination method that is used for the detection and localization of leaks. It can be used to test weld joints, braze or solder joints, and through all types of ferrous and non-ferrous metals with leak rates as low as 1.0 x 10-9 cc he/sec. Pressure testing is another method of verifying the integrity of a brazed or weld joint and has the capability of testing up to 500psi. Most of our test fixtures are designed and fabricated in-house. From a prototype or "one-off" part to large production runs.

Facilities

Thermal Processing (Brazing, Soldering & Heat Treating)

Support Equipment for Machining and Assembly

Testing & Inspection

General

Facilities

Metal Joining & Heat Treating Process

Since 2006, Brazecom Industries, LLC has focused on a variety of metal joining technologies and heat-treating processes. Whether you need brazing for commercial or military applications, our experts can handle even the most challenging ones.

Quality Services

Combining our decades of expertise and cutting-edge technology, we specialize in microwave components and assemblies, which otherwise require dissimilar metals. We take pride in delivering higher standards of product quality, on-time delivery, and unmatched service.